Blog

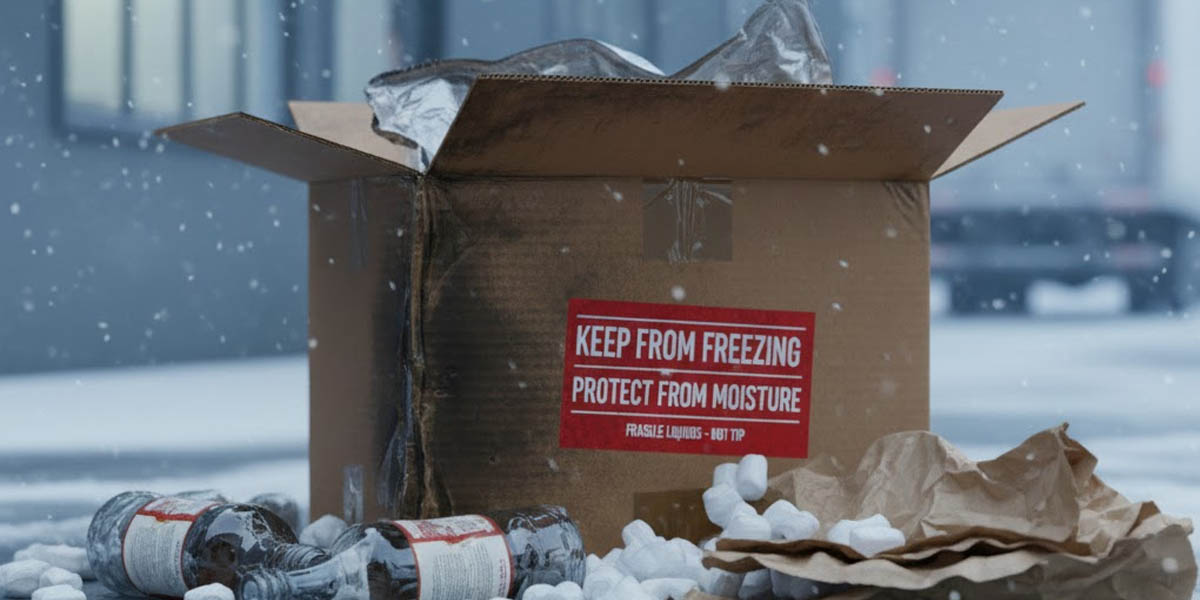

Winter doesn’t just make logistics slower. It makes packaging honest.

When temperatures drop, every weak link shows up faster: tape loses grip, cartons soften, cushioning stiffens, condensation destroys labels, and “it was fine on the dock” turns into “it arrived ruined.” Strong companies don’t treat this as bad luck. They treat winter like a yearly debrief: what failed, what almost failed, and what needs upgrading before the next cold snap.

Below are the 10 most common winter packaging fails - each with a quick “debrief” and the prevention playbook used by teams that ship reliably when conditions get ugly.

1) Fail: Assuming “regular” packaging survives winter

Debrief: “We shipped in our standard box. Everything looked fine at dispatch. By the time it reached the customer, the carton was soft, wet, and crushed.”

How strong teams prevent it:

- Use winter-rated board grades (stronger corrugate, higher ECT/BCT), plus moisture-resistant coatings where needed.

- Create winter variants of your core packaging—not “nice-to-have,” but mandatory for specific lanes and months.

2) Fail: Ignoring temperature sensitivity and insulation needs

Debrief: “The product arrived intact—but unusable. Frozen, separated, or damaged by cold.”

How strong teams prevent it:

- Map each SKU’s temperature tolerance and maximum exposure time (not just “keep cool,” but actual limits).

- Build winter SOPs that define:

- what must be insulated

- what must be expedited

- what must never ship without protection

3) Fail: Misusing (or overusing) coolants

Debrief: “We added extra gel packs ‘to be safe’… and accidentally froze half the shipment.”

How strong teams prevent it:

- Test coolant quantity, placement, and conditioning for winter profiles—not just summer.

- Standardize pack-outs with a simple diagram so every shift packs the same way (consistency beats heroics).

4) Fail: Not planning for condensation and moisture

Debrief: “The outside of the box was dry. Inside? Damp packaging and smeared labels.”

How strong teams prevent it:

- Use moisture barriers (sealed inner bags, liners) and humidity-resistant labels/inks.

- Design pack-outs that keep cold elements away from surfaces where condensation forms.

- Add desiccants where appropriate—especially for long dwell times.

5) Fail: Weak seals and closures in the cold

Debrief: “The tape that always worked in June started popping open in January.”

How strong teams prevent it:

- Choose tapes/adhesives rated for low temperatures and rough handling.

- Add double-seal rules for heavy, high-value, or long-route shipments:

- H-taping

- strapping/strapping + stretch

- tamper-evident seals where needed

6) Fail: Over-trusting void fill and cushioning

Debrief: “Cushioning looked perfect at pack-out. Product still arrived cracked.”

How strong teams prevent it:

- Remember: some padding materials stiffen in cold and stop absorbing shock.

- Run drop, vibration, and compression tests at realistic winter temperatures.

- Eliminate “floating” items: aim for zero movement inside the box.

7) Fail: Forgetting trailers and depots are colder than you think

Debrief: “We assumed ground shipping meant room temperature. It didn’t.”

How strong teams prevent it:

- Treat trailers, cross-docks, and last-mile vans as uncontrolled environments.

- Align service level + packaging to real exposure:

- insulation for long-haul ground

- expedited options for highly sensitive SKUs

- buffer stock closer to demand where possible

8) Fail: No winter-specific labeling and handling cues

Debrief: “Carriers didn’t realize it was sensitive, so it sat outside for hours.”

How strong teams prevent it:

- Add clear seasonal handling instructions:

- “Do not leave outside”

- “Keep above X °C/°F”

- “Protect from moisture”

- Use scannable and highly visible cues (color-coded labels, QR to handling SOP) that warehouse and carriers can’t miss.

9) Fail: Ignoring customer experience during peak winter gifting season

Debrief: “The product survived—but the box arrived soggy, scratched, and felt cheap for a holiday gift.”

How strong teams prevent it:

- Create winter-safe branded variants:

- moisture-resistant finishes

- abrasion-resistant sleeves

- protective outer shippers for premium boxes

- Protect the “unboxing moment” with materials that survive wet ramps, snow, and handling friction.

10) Fail: Skipping the winter post-mortem

Debrief: “We fix the same winter problems every year because we never document them.”

How strong teams prevent it:

- Run a short, structured debrief each March:

- failures

- near misses

- customer complaints

- carrier damage patterns

- Convert findings into:

- updated packaging specs

- revised packing instructions

- staff training before next season

Wrap-up: Turn winter into your best test

Strong companies treat winter as a stress test they can learn from—not just a season to survive. If your team sees broken goods, wet cartons, or a spike in refunds every time temperatures drop, the solution isn’t “work harder.” It’s package smarter.

If you want this to be actionable immediately, do one thing this week:

Pick your top 10 winter SKUs and run a winter pack-out review—materials, sealing, moisture protection, labeling, and transit time assumptions.

If you share your product type, routes, and your worst winter failure, we can recommend a winter-ready packaging spec (and a simple test plan) so the next cold snap doesn’t hit your margins.