Blog

Packaging, Labeling, and Documentation

Proper cargo preparation is a critical stage in the shipping process—it ensures not only the safety of goods but also faster delivery, smoother customs clearance, and fewer warehousing issues. This is especially important when dealing with large-volume or international shipments. Below is a structured checklist to help entrepreneurs organize cargo shipments professionally and with reduced risk.

✅ 1. Packaging: Protecting Goods from Damage

The main purpose of packaging is to safeguard goods from mechanical damage, moisture, dust, and temperature fluctuations, while also making handling and storage easier.

What to do:

- Choose packaging appropriate to your cargo type (e.g., cardboard boxes, pallets, wooden crates, drums, containers).

- Use protective materials such as stretch film, foam padding, bubble wrap, or inserts—especially for fragile items.

- Ensure the packaging is strong enough to withstand stacking, vibrations, and potential shocks during transit.

- For oversized, heavy, or high-value cargo, consider ordering custom-made packaging tailored to the shipment's specifications.

- Test the packaging for stackability and compatibility with loading equipment (e.g., forklifts or pallet jacks).

Tip: For international shipments, make sure all wooden packaging materials are heat-treated and marked in compliance with ISPM 15 regulations.

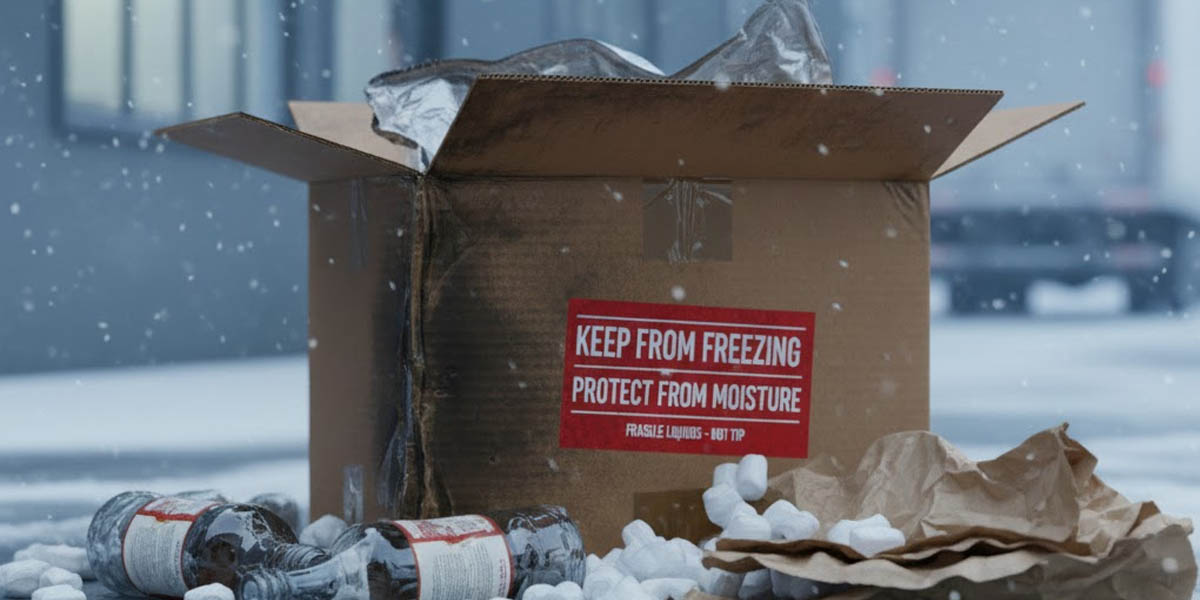

✅ 2. Labeling: Essential Information for Handling and Identification

Labeling helps logistics teams identify, sort, and handle cargo efficiently while minimizing the risk of mishandling.

What to include:

- Full names and contact details of the consignor and consignee (sender and receiver).

- Weight, dimensions, and number of packages or handling units.

- Purpose of shipment (e.g., export, transit, express).

- Standard handling symbols such as “Fragile,” “This Side Up,” “Do Not Tilt,” “Keep Dry,” etc.

- Hazard labels for dangerous goods, in compliance with international standards (e.g., ADR, IMDG).

- Barcode, QR code, or a tracking/shipping label (if applicable).

Tip: Ensure that all labels and markings are waterproof, durable, and clearly visible on at least two opposite sides of the package.

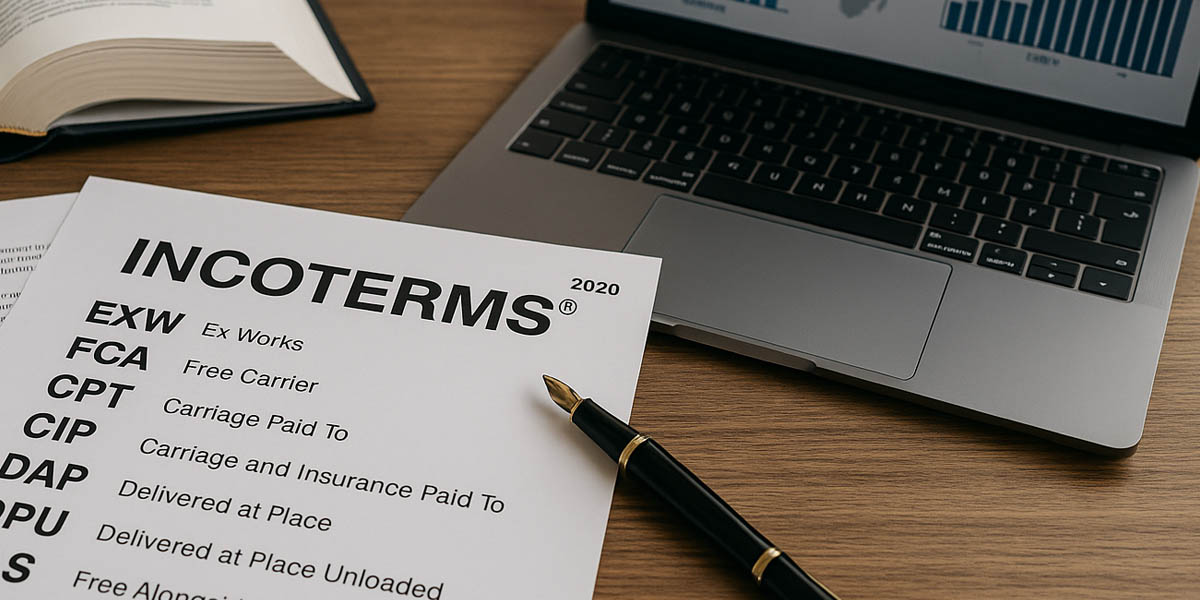

✅ 3. Documentation: Accompanying and Customs Papers

Accurate and complete documentation ensures the legal movement of goods and smooth passage through customs and checkpoints.

Essential documents (depending on the shipment type):

- Bill of lading (e.g., CMR for road, air waybill, rail waybill).

- Commercial invoice with a detailed description of the goods, quantity, unit price, total value, and currency.

- Packing list detailing the contents of each package or pallet.

- Sales or delivery contract, if part of a cross-border transaction.

- Certificates of conformity and origin, where required.

- Customs export/import declarations (mandatory for international shipments).

- Insurance policy, if cargo is insured.

- Permits and licenses for hazardous or special-category cargo, if applicable.

Tip: Ensure all documents meet the legal requirements of the shipper’s country, the carrier, and the destination country. For international shipments, documentation should be in English or at least bilingual.

✅ 4. Final Pre-Dispatch Checks

Before handing the shipment over to the carrier, confirm the following:

✔ The packaging is intact, properly sealed, and secure.

✔ Labels are readable and correctly placed.

✔ All required documentation is prepared and handed over.

✔ Photos of the cargo are taken (if needed).

✔ All parties involved (warehouse, carrier, consignee) have been informed.

✅ Conclusion

Properly preparing your cargo significantly reduces the risk of damage, delays, and disputes with carriers or customs authorities. Use this checklist as a foundational part of your logistics process—it will help streamline operations, reduce costs, and ensure a higher level of service for your clients.

If you ship regularly, consider automating your packaging, labeling, and documentation workflows using ERP or WMS systems. This will minimize manual errors and accelerate your logistics chain.